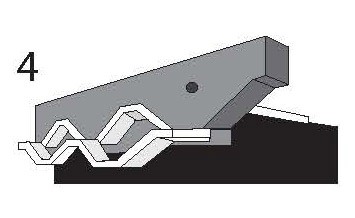

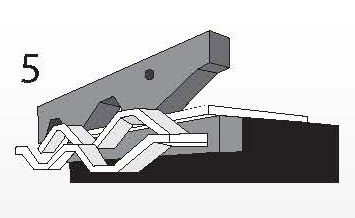

Process

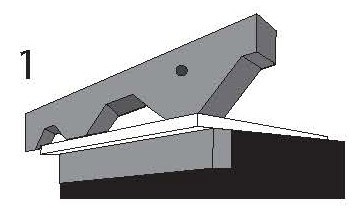

Metal Advances one strand width.

Die forms one-half of design.

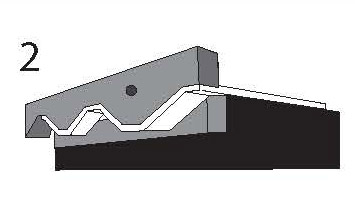

Press opens, indexes, (slides over half diamond) and . . .

. . . die descends, completing.

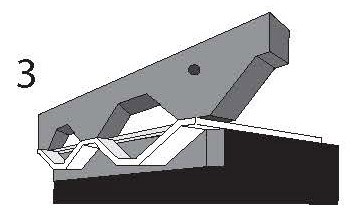

Press opens, and above steps are repeated continuously.

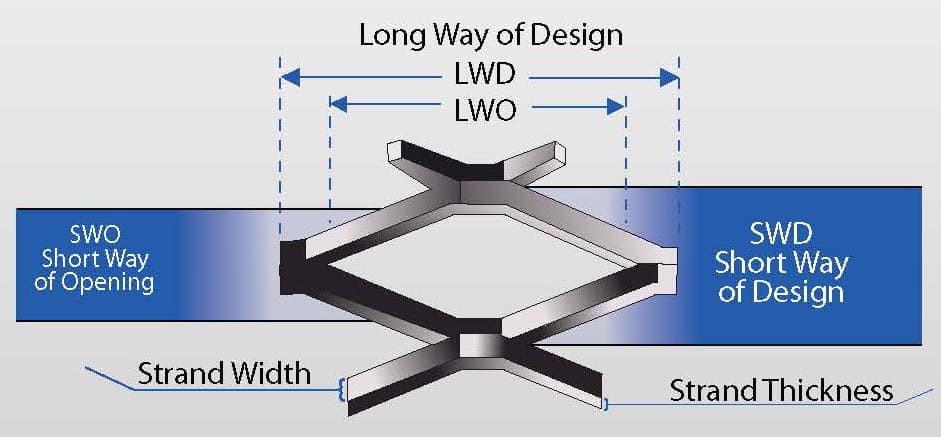

Terminology

Bond

The solid intersection of two strands

SWD

Nominal dimension, Short Way of Diamond

LWD

Nominal dimension, Long Way of Diamond

Design Size

Actual dimension SWD and LWD. Measured form a point to a corresponding point on the adjacent diamond

SWO

Short Way of Opening

LWO

Long Way of Opening

Strands

The sides of the expanded metal design

Strand Thickness

Thickness of the base metal

Strand Width

Amount of material fed under dies to produce one strand

Diamonds

Open area of metal after expanding

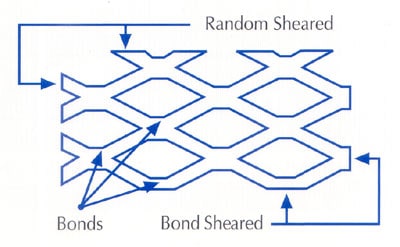

Edge Configuration

Condition of edge of an expanded metal sheet. Usually refers to “open” (random) or “closed” (bonded) diamond edges produced from shearing

Flattened

(abbreviated F) Expanded metal that has been cold-rolled after expansion to provide a smooth, flat and level sheet. The flattening process reduces the original thickness of the base metal

Grating

Expanded metal that is produced from heavier plate, usually low-carbon steel, with larger diamonds. It is typically used for walkways and platforms

Machine Run

Stock size pieces as manufactured (without being sheared to size)

Meshes

A term used to describe special expanded metal products

Shearing

Cutting expanded metal to produce various sizes and shapes (The standard is “random shearing”. If the buyer desires “bond shearing” that must be specified at order entry)

Standard

(abbreviated S) (Same as “Regular” or “Raised”) Expanded metal as it comes from the press. The strands and bonds are set at a uniform angle to the plane of the sheet. This gives added strength and rigidity, as well as skid-resistant surface

Style Designation Format

A combination of numbers, letters and abbreviations in a standard format permitting proper specification of dimension, thickness, style and weight of most commonly used expanded metal products (e.g. 3/4 #9, or 4.0 lb.)

Tolerances

Stock Size or Machine Run Sheets:

SWD

- Shall not vary greater than -0″ +1/4″ per foot of width (i.e. 48″ could be 49″)

LWD

- Shall not vary greater than -0″ + 1/4″ per foot of length (i.e. 96″ could be 98″)

Random Sheared

- Expanded metal +/- 1/8″ (open diamonds 4 sides)

- Grating +/- 1/4″

- Mini Mesh +/- 1/16″

Bond Sheared

- (LWD) +/- 1/2 of the width of the diamond (LW)

- (SWD) +/- 1/2 of the width of the diamond (SW)

Mini Mesh

- (LWD) +/- 1/8″

- (SWD) – 0 + 3/8″